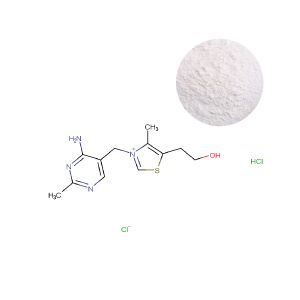

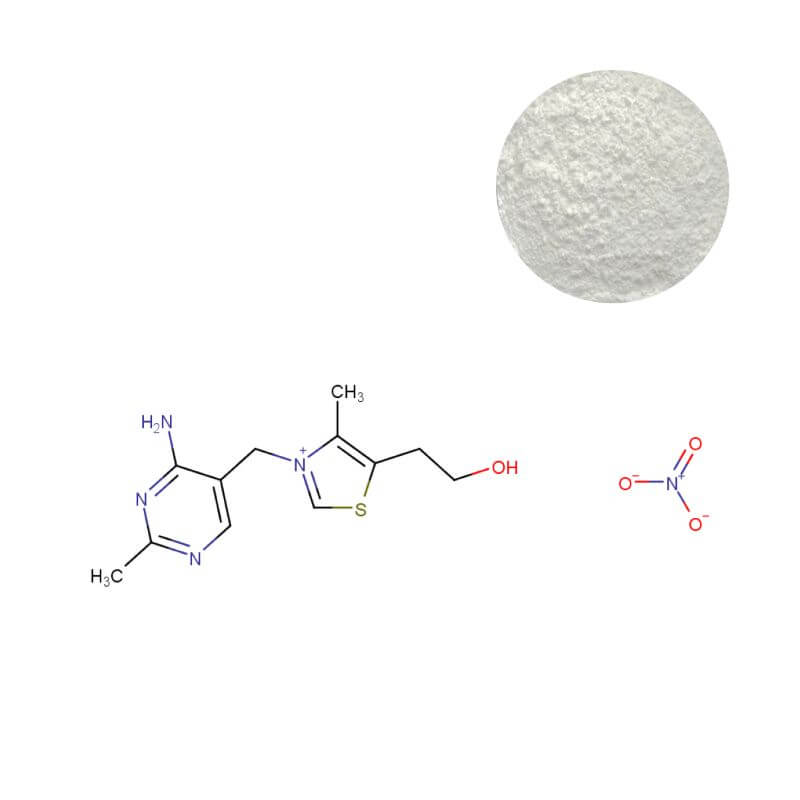

Thiamine Mononitrate

| Product Name | Thiamine Mononitrate (Vitamin B1 Nitrate) |

| CAS Number | 532-43-4 |

| Appearance | White to slightly yellow crystalline powder |

| Purity | ≥ 99% (HPLC) |

| Packaging | 1 kg/bag, 25 kg/drum |

| MOQ | 1 kg |

Thiamine Mononitrate: The Stability-Engineered Vitamin B1 for Predictable Product Performance

Do inconsistent vitamin assay results in your fortified products lead to compliance issues or batch rejection risks? For those of us developing products in food, feed, and supplements, consistency isn't just a goal—it's a fundamental requirement. Often, the root of such variability isn't vitamin B1 itself, but a mismatch between the selected form and your application's specific environmental stresses. Thiamine Mononitrate is engineered precisely to address stability challenges posed by moisture and pH. At Oclean Nutra, our partnership with global brands centers on delivering predictable performance, not just bulk powder. We provide the technical data, supply chain certainty, and formulation support necessary to ensure your product delivers its promised nutritional value from production to the end consumer.

Why Formulation Science Dictates Thiamine Mononitrate as the Strategic Choice

A common question arises: if both forms provide the same active nutrient, why does the salt matter? The answer becomes clear when considering real-world logistics and shelf-life demands. The defining advantage of Thiamine Mononitrate is its exceptionally low hygroscopicity. Practically speaking, its nitrate salt structure absorbs far less environmental moisture than the hydrochloride form. For your production line, this translates to tangible benefits. In comparative studies under conditions like 75% relative humidity, Thiamine Mononitrate retains its free-flowing properties and labeled potency significantly longer. This directly impacts your operational efficiency and bottom line: it reduces caking in silos and mixers, ensures more consistent blending in dry premixes, and mitigates the risk of potency failures that can trigger costly recalls. In essence, it's the most reliable method to guarantee that what's stated on your label is precisely what's in your product.

Targeted Applications: Where Stability Becomes a Critical Business Advantage

The stability profile of Thiamine Mononitrate goes beyond a mere technical specification; it is a direct contributor to product integrity and commercial success. Opting for a less stable form in the following key applications introduces entirely preventable risk.

- Animal Nutrition & Feed Premixes: This application is unequivocal. Modern premixes frequently contain choline chloride, a compound known to rapidly degrade Thiamine HCl. Industry data consistently shows that Thiamine Mononitrate can demonstrate over 5 times greater stability in such challenging matrices. This magnitude of improvement is critical—it ensures the nutritional value specified for livestock is what they actually consume, safeguarding both animal health and the return on investment for your formulation.

- Food Fortification & Dry Blends: From wheat flour and baking mixes to breakfast cereals and nutritional bars, global supply chains subject products to diverse climatic conditions. A form prone to moisture absorption risks clumping, texture alteration, and microbial growth. Thiamine Mononitrate prevents these issues, directly enabling the extended shelf life (typically 18-24 months) required by retailers. As the global fortified foods market expands, this inherent stability is key to successful entry into new, humidity-sensitive regions.

- Cosmetic & Personal Care: In vitamin-fortified creams and lotions with neutral pH, ingredient stability is paramount for maintaining perceived efficacy. The resilience of Thiamine Mononitrate in these formulations helps uphold product claims throughout its lifespan, adding a reliable, functional component to your portfolio.

Strategic Ingredient Selection: Matching the Right B1 Form to Your Project Goal

Selecting the appropriate Vitamin B1 form is a pivotal formulation decision. The framework below is designed to guide your choice based on desired product outcomes.

- For Unmatched Stability in Dry/Food/Feed Systems: Your search concludes with Thiamine Mononitrate. It is the industry-proven standard for any application where moisture control and long-term potency are the primary concerns.

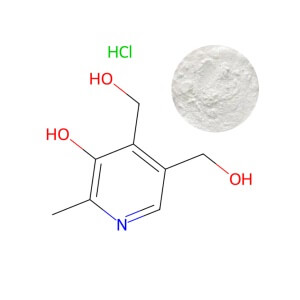

- For High-Solubility Liquid Applications: In beverages, syrups, or liquid concentrates where solubility is paramount, we recommend Vitamin B1 Thiamine HCl. Its high water solubility guarantees clear solutions and rapid bioavailability, making it the ideal choice for RTD drinks and therapeutic syrups.

- For Advanced Bioavailability in Specialty Supplements: When targeting superior absorption for specific health formulations—such as those for nerve support—our premium Benfotiamine Powder offers a distinct fat-soluble advantage. Its unique properties facilitate significantly higher tissue uptake, creating a powerful point of differentiation for your finished product.

We maintain this comprehensive portfolio so you can source all your Vitamin B1 requirements from a single, strategic partner equipped with deep technical expertise in each variant's optimal application.

Quality and Compliance: A System Designed for Your Peace of Mind

We understand the complexity of regulatory submissions and the value of your quality team's time. Consequently, our quality assurance framework is built for seamless integration into your vendor management systems. We partner with a select network of leading, GMP-certified manufacturers, conducting rigorous audits to ensure consistency at the source. Every batch is verified against stringent specifications, including Purity (≥99% by HPLC), Loss on Drying (≤1.0%), and heavy metal limits (e.g., Lead ≤2.0 mg/kg) that comply with global pharmacopoeia standards (USP/EP). Our commitment extends beyond the Certificate of Analysis. We provide a complete, ready-to-use documentation package—encompassing certificates of analysis, detailed specifications, and compliance statements—typically within 24 hours of your request. This proactive approach is designed to drastically reduce your qualification timeline and mitigate compliance risk.

Partnership Logistics: Supply Chain Reliability and Expert Support

Your success hinges not only on a quality ingredient but on a reliable partnership. Our supply chain model is engineered for both flexibility and transparency. With a 1 kg Minimum Order Quantity (MOQ), you can pilot new formulations with minimal upfront commitment. Standard 25 kg fiber drums, equipped with sealed, moisture-proof inner liners, guarantee the product arrives at your facility with its integrity fully intact. More importantly, engagement with our team means direct access to experts. We provide actionable insights on blending sequences, stability expectations in various matrices, and the technical data needed to support your R&D and QC workflows. Our objective is to function as an extension of your team, helping you de-risk production and accelerate your time-to-market.

Your Next Step: Optimize Product Integrity with Confidence

In today's market, where consumer trust is paramount and regulatory scrutiny intensifies, ingredient stability forms your first and most critical line of defense. Transitioning to Thiamine Mononitrate is a decisive move to eliminate preventable variance and solidify your brand's reputation for unwavering quality.

Allow us to help you validate this strategic choice. We offer more than a sample; we propose a collaboration tailored to ensure success in your specific application.

Frequently Asked Questions

Share this product

Related Products

Ready to get started?

Contact our team for technical specifications, pricing, and customized solutions.