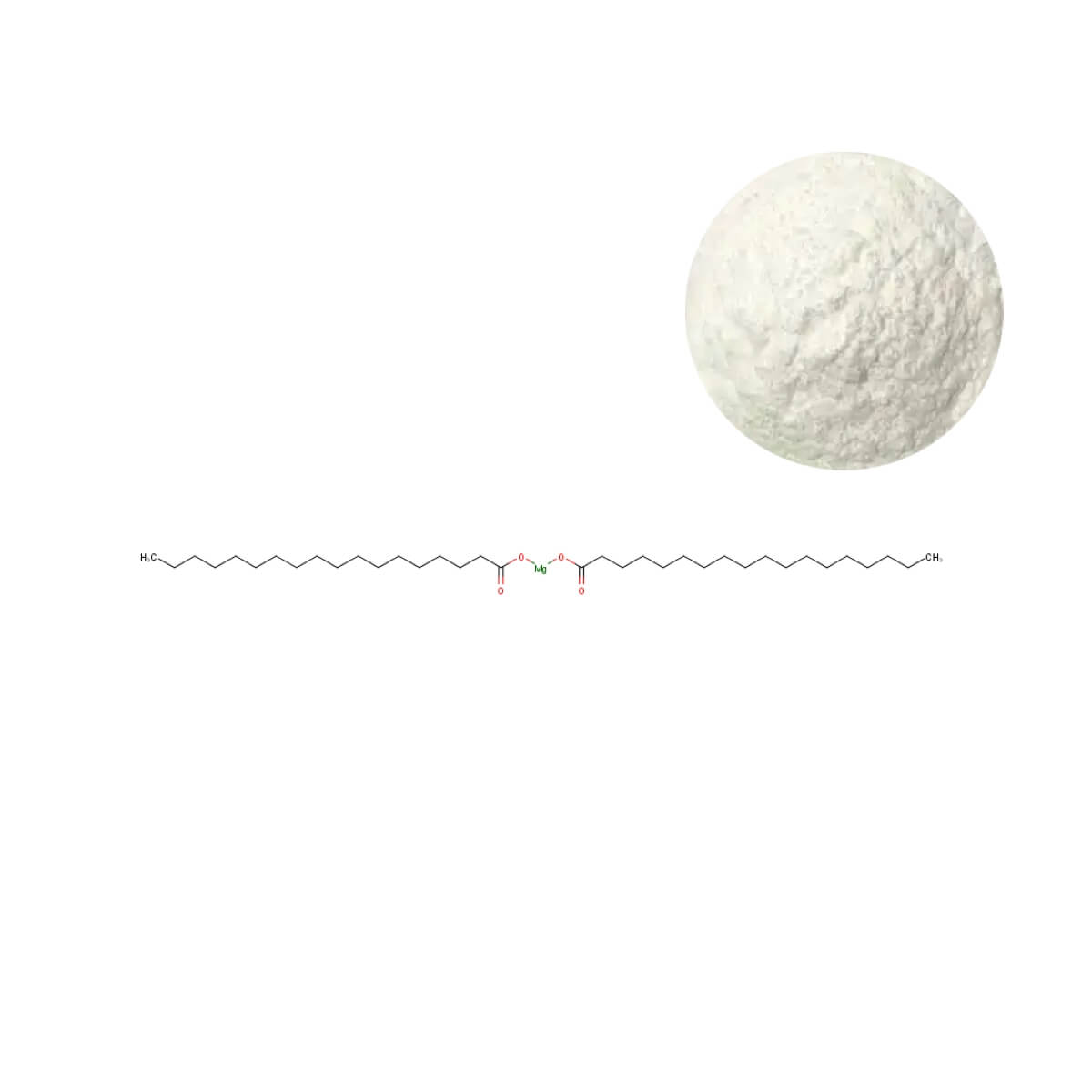

Magnesium Stearate Powder

| Product Name | Magnesium Stearate Powder |

| CAS Number | 557-04-0 |

| Appearance | Fine white powder |

| Grade/Standard | Food Grade, FCC Compliant |

| Packaging | 25 kg / bag |

| MOQ | 25 kg |

Solve Tablet Production Challenges with High-Performance Magnesium Stearate

Tablet sticking. Inconsistent powder flow. These manufacturing headaches slow down production, increase waste, and drive up costs—problems we hear about daily from supplement and food producers. Our magnesium stearate powder specifically targets these issues with performance consistency that keeps production lines moving. As a specialized supplier to the industry, we understand what manufacturers truly need: reliable excipients, batch-to-batch consistency, and accessible technical support.

What Is Magnesium Stearate and Why It Matters

Magnesium stearate (C₃₆H₇₀MgO₄) isn't just another additive—it's the magnesium salt of stearic acid that serves as your essential manufacturing partner. In practical terms, it's what prevents your carefully developed formulations from sticking to equipment during high-speed compression. This fine white powder becomes indispensable when producing nutraceutical tablets or food supplements at scale. The difference is clear: either you're constantly stopping for cleaning, or you're maintaining steady output. Many clients report reducing machine downtime by 15-30% after switching to our magnesium stearate.

Real Benefits for Your Production Line

When you incorporate our magnesium stearate into formulations, you're investing in smoother production and superior end products. Here's what manufacturers typically experience:

- Superior lubrication that extends equipment life: Dramatically reduces friction between powder blends and metal surfaces of tablet punches and dies. This translates to less wear on machinery components and fewer production halts. One client saw their tooling last 40% longer after switching.

- Reliable anti-adhesion performance: Eliminate powder blends clinging to equipment surfaces or forming problematic clumps. This consistency ensures uniform tablet composition and structural integrity batch after batch—critical for meeting quality control standards.

- Improved powder flow characteristics: By reducing inter-particle friction, your blends move more predictably through feeding systems into tablet presses or capsule fillers. The result? More accurate dosing and consistent product weight that slashes rejection rates.

- Predictable disintegration profiles: When used at proper concentrations, it maintains excellent lubricating properties while allowing finished tablets to break apart correctly upon consumption. This balance ensures active ingredients remain bioavailable without production compromises.

- Reduced operational costs: Fewer machine stoppages, less material waste, and consistent output all contribute to better bottom-line results. Most operations see cost savings of 8-12% in reduced downtime and material waste.

Our Practical Quality Approach

Working exclusively with B2B clients, we take quality beyond basic certifications. While maintaining full GMP compliance and providing detailed Certificates of Analysis with every batch, our approach is more hands-on. We regularly visit manufacturing partners to verify processes and maintain retention samples of every batch for two years. Our quality checks focus on parameters that matter in production: consistent particle size distribution (tight tolerances of 15-25 microns), minimal heavy metal content (below 10ppm), and controlled moisture levels (loss on drying under 2.5%). This practical focus means you get a product that performs consistently in real manufacturing environments.

Vegetable-Based Sourcing for Modern Markets

Today's consumers and manufacturers care about ingredient origins. Our magnesium stearate comes exclusively from non-GMO vegetable sources, making it suitable for various dietary preferences and global regulatory requirements. This plant-based origin aligns with growing demand for cleaner labels in nutraceutical and food industries. The product consistently meets Food Chemicals Codex (FCC) specifications and complies with major international standards for food and supplement applications. We maintain full traceability from source to delivery, giving you confidence in your supply chain.

Technical Specifications for Manufacturing Realities

We've structured our offerings based on feedback from production environments. Key details when placing an order:

- Purity: Minimum 99% magnesium stearate content with batch-to-batch consistency

- Appearance: Fine white powder with uniform texture

- Minimum Order Quantity: 25 kilograms with flexible arrangements for partners

- Packaging: 25 kg bags with moisture-resistant lining—customization available

- Shelf Life: 24 months stored in cool, dry conditions away from direct light

- Lead Times: Typically 7-10 days for standard orders, expedited options available

- Customization: Alternative packaging, particle size adjustments, or documentation based on your needs

Common Applications Where Our Magnesium Stearate Performs

Clients use our magnesium stearate across various applications with consistent results:

- Nutraceutical tablets: From multivitamins to specialized supplements, reliable performance without compromising disintegration

- Food supplement capsules: Ensures smooth filling operations and consistent dosage

- Food additive applications: Where approved as a release agent or flow aid

Let's Optimize Your Production

When sourcing manufacturing ingredients, you need more than product—you need responsive support and reliable supply. We've helped numerous supplement brands and food manufacturers address specific production challenges with consistent, high-performing magnesium stearate. Whether reducing tablet defects, improving machine efficiency, or ensuring regulatory compliance, we bring both product quality and practical industry experience. Want to see how our magnesium stearate could improve your operation? Contact us for current pricing and sample availability. We respond to inquiries within 2 hours on business days and can arrange samples for qualified manufacturers within 48 hours.

Frequently Asked Questions

Share this product

Related Products

Ready to get started?

Contact our team for technical specifications, pricing, and customized solutions.