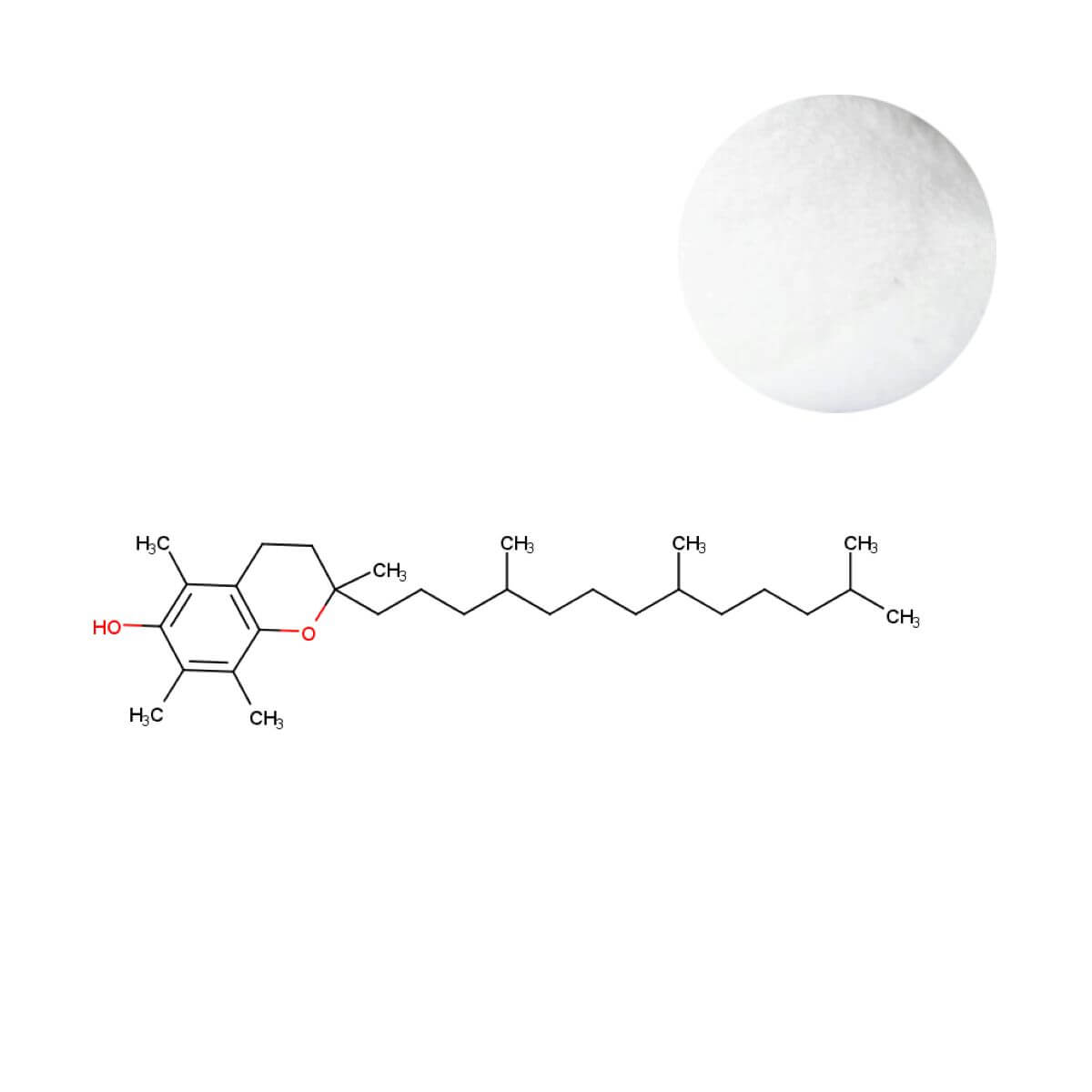

d-α-Tocopherol Powder

| Product Name | Vitamin E d-alpha-Tocopherol Powder |

| CAS Number | 59-02-9 |

| Appearance | White to off-white free-flowing powder |

| Activity | 500 IU/g |

| Packaging | 20kg/drum, customizable |

| MOQ | 1 kg |

Vitamin E d-alpha-Tocopherol Powder: Foundational Cellular Protection for Advanced Health Formulations

Ingredient selection is a strategic decision for brands in the premium wellness space, directly impacting product efficacy and market credibility. With the clear shift towards proactive, science-backed health, foundational nutrients with definitive biological roles are paramount. Natural d-alpha-Tocopherol Powder is the primary lipid-soluble antioxidant in human physiology, making it essential for serious formulations targeting longevity, metabolic function, and cognitive support. The central challenge lies in sourcing a bulk ingredient where promised bioactivity consistently translates into finished-product results. This depends on precise specifications, such as standardization to 500 IU/g (HPLC, USP <551>), which quantifies physiological potency rather than merely chemical purity. The following guide provides a strategic framework for leveraging this essential nutrient, enabling the development of superior, differentiated products that deliver on their claims.

The Science of Cellular Defense: Beyond Generic Antioxidant Claims

Understanding the specific, dual-action mechanism of d-alpha-Tocopherol is crucial for effective product positioning and for justifying its role in advanced formulas. It moves the narrative from a generic “contains antioxidants” to a precise statement of protecting cellular integrity through targeted pathways.

Natural d-alpha-Tocopherol serves as the principal guardian of cell membranes against lipid peroxidation, a chain reaction that damages cellular integrity. Its protective role operates through two key mechanisms. First, it directly quenches peroxyl radicals within lipid bilayers, safeguarding polyunsaturated fatty acids. This action makes it indispensable for formulations targeting cells with high lipid content or exposure to oxidative stress, such as those in skin, neurological, and cardiovascular health products.

Beyond this classic antioxidant function, research points to non-antioxidant signaling roles. Evidence indicates alpha-tocopherol can modulate cell signaling and gene expression by interacting with specific receptors like the 67 kDa laminin receptor (DOI: 10.1016/j.jnutbio.2022.109129). This suggests its benefits extend from passive protection to active cellular regulation. For formulators, this dual mechanism translates into a foundational, multifunctional benefit rather than a transient effect.

Clinical evidence underscores its relevance in addressing oxidative stress. For instance, a randomized, double-blind, dose-finding study (NCT04801849) investigated daily doses of 200 IU to 800 IU of d-alpha-Tocopherol in adults with non-alcoholic fatty liver disease (NAFLD). This study design highlights the application of specific, high-dose Vitamin E protocols in clinical metabolic health research. For brands developing research-informed products in this segment, aligning with such clinical investigation strengthens product dossiers and communication.

Quality Decoded: Why IU/g and Contaminant Limits Are Your True Benchmarks

Scrutinizing a Certificate of Analysis (CoA) for the correct parameters is a direct exercise in risk management. This practice shifts the procurement focus from price-per-kilo to total cost of ownership, preventing issues related to under-dosing, regulatory hurdles, or supply chain disruption.

For brands sourcing bulk Natural d-alpha-Tocopherol Powder, the specification sheet tells the story of safety and efficacy. The most critical metric is Vitamin E activity expressed in International Units per gram (IU/g). A specification of 500 IU/g, confirmed via HPLC (USP <551>), measures biological potency directly. This assurance means your manufacturing team can rely on consistent raw material to achieve precise label claims, batch after batch.

Contaminant limits are equally vital, reflecting a supplier’s adherence to global safety standards. Premium material should meet stringent specifications that align with or surpass international guidelines:

| Parameter | Premium Specification | Business Impact & Insight |

|---|---|---|

| Heavy Metals | Pb ≤2.0 ppm, As ≤2.0 ppm, Cd ≤1.0 ppm, Hg ≤1.0 ppm | These limits often exceed general food ingredient standards. Proactively sourcing material meeting a lead limit of 2.0 ppm, for example, provides a compliance safety buffer for global markets and mitigates risk against potential regulatory tightening. |

| Microbiological Quality | Total Plate Count ≤1,000 CFU/g; Absence of Pathogens | Conformance to USP <61>/<62> standards is a baseline expectation for ingestible ingredients. A supplier’s consistent performance here protects your brand from costly recalls and reputational damage. |

From a compliance standpoint, d-alpha-Tocopherol is well-established. It holds GRAS (Generally Recognized as Safe) status in the United States and is considered a traditional food component (vitamin) in the European Union. In markets like China, it is approved for use in registered health foods. Consequently, during supplier evaluation, verifying access to relevant regulatory documentation is as critical as reviewing the specifications, as it directly impacts your speed to market.

Formulation in Practice: Synergy, Stability, and Effective Delivery

Mastering the practical application of d-alpha-Tocopherol is where R&D expertise translates directly into product performance and shelf-life. This knowledge prevents costly reformulations and ensures the ingredient's intended potency reaches the consumer.

Effective formulation requires optimizing d-alpha-Tocopherol for stability, synergy, and bioavailability. The common daily dose in supplements ranges from 100 IU to 400 IU, with clinical studies investigating doses up to 800 IU for specific applications.

For enhanced efficacy and product differentiation, consider these strategic synergies:

- With Vitamin C and other network antioxidants: This classic combination is grounded in the "antioxidant network" theory, where Vitamin C regenerates oxidized Vitamin E in the aqueous phase (DOI: 10.1016/j.freeradbiomed.2024.02.013). This synergy enables a more robust and sustained antioxidant effect in vivo—a compelling claim for advanced formulas. Pairing with mixed tocopherols oil further broadens the antioxidant defense spectrum.

- In comprehensive wellness blends: It integrates seamlessly into formulas for metabolic, cognitive, or skin health, providing foundational antioxidant support alongside other targeted nutrients.

The primary stability challenge for the powder form is oxidation from heat, light, and oxygen. A critical, often overlooked, factor is controlling environmental humidity during production (keeping it below 45%). This is frequently more crucial for preventing caking and degradation than relying on final opaque packaging alone. Key manufacturing steps include:

- Blending in a controlled, low-humidity environment to maintain powder flowability.

- Employing nitrogen flushing in final packaging to displace oxygen and extend shelf-life.

- Utilizing encapsulating agents or opting for dry dosage forms like tablets, which offer superior protection compared to oil-filled softgels.

Mitigating Sourcing Risk: The Due Diligence Checklist for Procurement

Supplier selection is fundamentally about de-risking your supply chain. This checklist shifts the evaluation beyond unit price to factors ensuring long-term reliability and protecting brand equity.

Choosing a supplier for a foundational nutrient like d-alpha-Tocopherol is a strategic decision. The lowest price per kilogram often carries elevated risk in the form of inconsistent activity or regulatory complications. Expert procurement teams assess partners against a clear checklist:

Technical & Quality Documentation:

- Does the supplier provide a comprehensive, batch-specific CoA with HPLC-verified IU/g activity and full contaminant profiles? Request historical CoAs to verify consistency.

- Can they provide valid GMP and relevant food safety certifications (e.g., FSSC 22000) for their manufacturing facilities?

- Do they readily share regulatory documentation, such as GRAS determinations, to reduce your compliance burden?

Supply Chain & Service Evaluation:

- Can they demonstrate batch-to-batch consistency through CoA trends? Transparency here signals process control.

- Do they offer technical support and formulation guidance? This partnership value can accelerate your development timeline.

- Is their packaging (e.g., 20kg/drum with double-lined bags) robust for international shipping? Inadequate packaging is a common source of quality disputes.

- Is their system for handling samples and documentation responsive and transparent?

A partner excelling in these areas minimizes the risk of production delays and compliance issues, ensuring a superior total cost of ownership. For procurement, the ability to present a thorough evaluation based on these criteria justifies a partnership that offers long-term value over short-term savings.

Next Steps for Your Product Development

Integrating a premium, reliably sourced Natural d-alpha-Tocopherol Powder provides a scientifically robust foundation for products demanding trust and efficacy. The strategic advantages—from its dual-action mechanism and stringent quality markers to its formulation versatility—are clear for brands aiming to lead in sophisticated health categories.

To transition from evaluation to application, a practical, hands-on assessment is the logical next step. Request your complimentary sample and complete technical dossier. This enables your R&D team to test performance in specific formulations and provides your regulatory department with the necessary documentation for review. This single step de-risks sourcing and can significantly accelerate your path to a market-ready, superior product.

Frequently Asked Questions

Share this product

Related Products

Ready to get started?

Contact our team for technical specifications, pricing, and customized solutions.