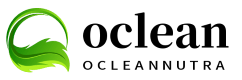

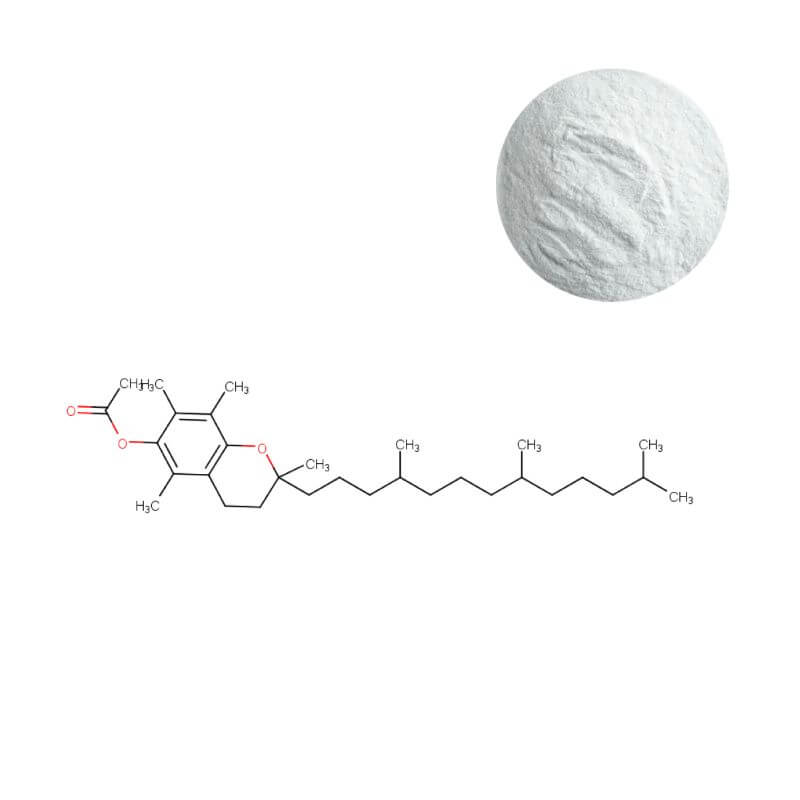

Vitamin E Acetate Powder

| Product Name | Vitamin E Acetate Powder (dl-α-Tocopheryl Acetate) |

| CAS Number | 7695-91-2 |

| Appearance | White to off-white fine powder |

| Activity | 500 IU/g |

| Packaging | 25 kg/drum, customizable |

| MOQ | 1 kg |

Vitamin E Acetate Powder: A Strategic Ingredient for Formulation Reliability and Market Compliance

For product developers, ingredient selection is a strategic decision with direct consequences for manufacturing success and brand integrity. While vitamin E's biological role is clear, its physical form as a raw material dictates production complexity and final product stability. Transitioning from an oil to a premium Vitamin E Acetate Powder addresses core industrial challenges: it eliminates the inconsistencies of liquid handling in solid dosage forms, guarantees blend uniformity, and extends shelf-life through superior oxidative stability. A material standardized to 500 IU/g activity (≥98.0% purity) and engineered into a free-flowing powder is more than a specification—it is a tool for mitigating production risk. This guide examines the strategic rationale for this ingredient, from the science underpinning its stability to the supply chain diligence needed for seamless integration.

Decoding the Science: Antioxidant Protection with a Stabilized Molecular Advantage

Justifying the specification of dl-alpha-tocopheryl acetate begins with understanding its molecular rationale. This knowledge directly supports your stability claims and helps prevent degradation in the final product. Vitamin E's fundamental role as the body's primary lipid-soluble antioxidant, protecting cell membranes from oxidative damage, is well-established. The strategic value of the acetate form lies in its chemistry: the ester bond safeguards the active phenol group during storage and processing. For brands, this means a more predictable raw material with a longer functional lifespan, directly protecting your product's potency claim from in-process oxidation.

Contemporary research further clarifies its involvement in cellular signaling and anti-inflammatory pathways (DOI: 10.1016/j.freeradbiomed.2021.11.027). A 2020 metabolomics study on subjects supplemented with α-tocopheryl acetate revealed specific metabolic shifts, highlighting complex biological interactions beyond basic antioxidant activity (DOI: 10.1158/1055-9965.EPI-20-0187). For formulation teams, this underscores a critical principle: consistent biological outcomes require the delivery of a consistent, high-purity molecule. Variability in the raw material introduces uncontrolled variables that can undermine the clinical research supporting your claims.

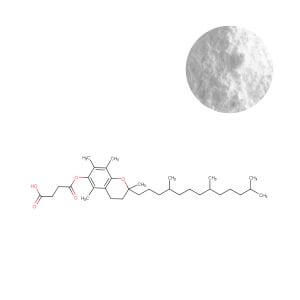

Commercial Decision Point: The choice between natural and synthetic forms often distills to brand positioning versus manufacturing precision. Natural d-alpha-tocopherol carries a market premium for its sourcing narrative. In contrast, synthetic dl-alpha-tocopheryl acetate delivers unmatched batch-to-batch consistency and oxidative stability. For brands where manufacturing reliability, scalable supply, and cost-effective delivery are priorities—particularly in high-volume lines like multivitamins—the synthetic acetate form presents a strategically sound advantage. When a natural profile is core to brand identity, natural d-alpha-tocopherol powder serves as the relevant alternative.

Beyond Purity: Quality Benchmarks That Predict Manufacturing Performance

A Certificate of Analysis (CoA) is more than a compliance document; it predicts how an ingredient will perform in your facility. Scrutinising the right parameters prevents costly processing issues before production begins. While high chemical purity (≥98.0%) is essential, functional performance hinges on other metrics.

- Heavy Metals & Contaminants: Adherence to strict limits (e.g., Lead ≤1.0 mg/kg) is a safety baseline. From a supply chain view, it signals a vendor's commitment to global standards, reducing your regulatory due diligence burden.

- Carrier System & Physical Properties: The carrier (e.g., maltodextrin, silica) determines manufacturability. Particle Size (≥95% through 80 mesh) is critical for content uniformity in tablets and capsules; deviation here can cause capping or weight variation. Similarly, Loss on Drying (≤5.0%) controls moisture, impacting flowability and long-term microbial stability.

The Compliance Footprint as a Strategic Asset: Regulatory status is a non-negotiable filter. GRAS status in the U.S. and compliance with standards like China's GB 1886.233—2016 are not mere checkboxes. They de-risk market entry and streamline your product's regulatory filing. A supplier providing clear, verifiable documentation on these points effectively accelerates your time-to-market.

Procurement Insight: Consequently, experienced procurement teams treat the CoA as a technical audit sheet. They correlate parameters like particle size distribution with their specific equipment, transforming a quality specification into a forecast of production efficiency.

Formulation Mastery: Translating Physical Form into Product Innovation

The powder form's greatest commercial value is its application versatility. It enables innovation in solid and hybrid dosage forms while simplifying production, expanding your development portfolio without requiring new manufacturing technology.

| Application | Strategic Advantage & Commercial Rationale |

|---|---|

| Tablets & Two-Piece Capsules | Enables direct compression or encapsulation without pre-blending with oil adsorbents. This simplifies the bill of materials, reduces processing steps, and minimises cross-contamination risk in facilities running multiple lines. |

| Powder Blends & Stick Packs | Offers instant dispersibility and avoids the oily residue that can compromise the sensory appeal and flow of premium powder products—a key factor for stable, single-serve formats in the growing on-the-go nutrition segment. |

| Functional Food Premixes | Allows for uniform fortification of dry matrices like cereals, flours, or instant drink mixes. This creates opportunities for fortifying everyday foods without altering texture or requiring special oil-mixing equipment at the co-manufacturer. |

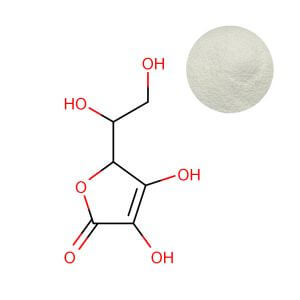

Synergy for Market Differentiation: Formulating with synergistic partners like Vitamin C creates a compelling "antioxidant network" story, a valuable marketing angle. For a broader tocopherol profile, combining with natural mixed tocopherols can support a premium, whole-food positioning.

Operational Protocol: Maximising the inherent stability of the acetate ester involves controlling the production environment. A practical, yet often overlooked, step is maintaining relative humidity below 45% during mixing—a measure that frequently impacts final product stability more directly than primary packaging alone.

Mitigating Supply Chain Risk: The Checklist for Strategic Sourcing

In global sourcing, an ingredient's true cost extends far beyond its unit price. Supply chain resilience, documentation integrity, and technical partnership are value drivers that protect brand revenue and reputation. A rigorous supplier evaluation framework is essential.

- Transparency & Traceability: Does the supplier provide full, batch-specific CoAs and traceability documentation? This is fundamental for quality audits and swiftly addressing any downstream regulatory inquiries.

- Technical Partnership Capability: Do they offer formulation support and troubleshooting? A partner who understands carrier interactions and blending mechanics can help avoid costly trial-and-error during scale-up.

- Regulatory & Customisation Agility: Are they equipped to support submissions in your target markets? Can they accommodate custom needs, from R&D-sized (1 kg MOQ) to full production orders? For projects requiring a different bioactive form, verify access to alternatives like Vitamin E Succinate Powder.

- Business Continuity Planning: Do they have validated second sources or safety stock protocols? This mitigates the single-point-of-failure risk that can halt production.

Total Cost of Ownership (TCO) Perspective: A supplier excelling in these areas may not offer the lowest initial price but significantly reduces hidden costs related to production downtime, quality failures, and regulatory delays. For a brand, this translates to predictable costing, reliable launch timelines, and secured market access.

Validating the Strategic Fit for Your Product Line

Selecting Vitamin E Acetate Powder is a decision that intersects R&D, operations, and regulatory strategy. It represents a commitment to manufacturing efficiency, product stability, and supply chain dependability. The final validation of this strategic fit, however, comes from practical testing within your specific formulation and process parameters.

To proceed with confidence, we recommend a hands-on, data-driven evaluation. Request a complimentary sample alongside the complete technical dossier. This package provides both the tangible material and the detailed documentation—including full CoAs, stability data, and application notes—enabling your team to assess performance in your own lab, de-risking integration and accelerating development.

Frequently Asked Questions

Share this product

Related Products

Ready to get started?

Contact our team for technical specifications, pricing, and customized solutions.