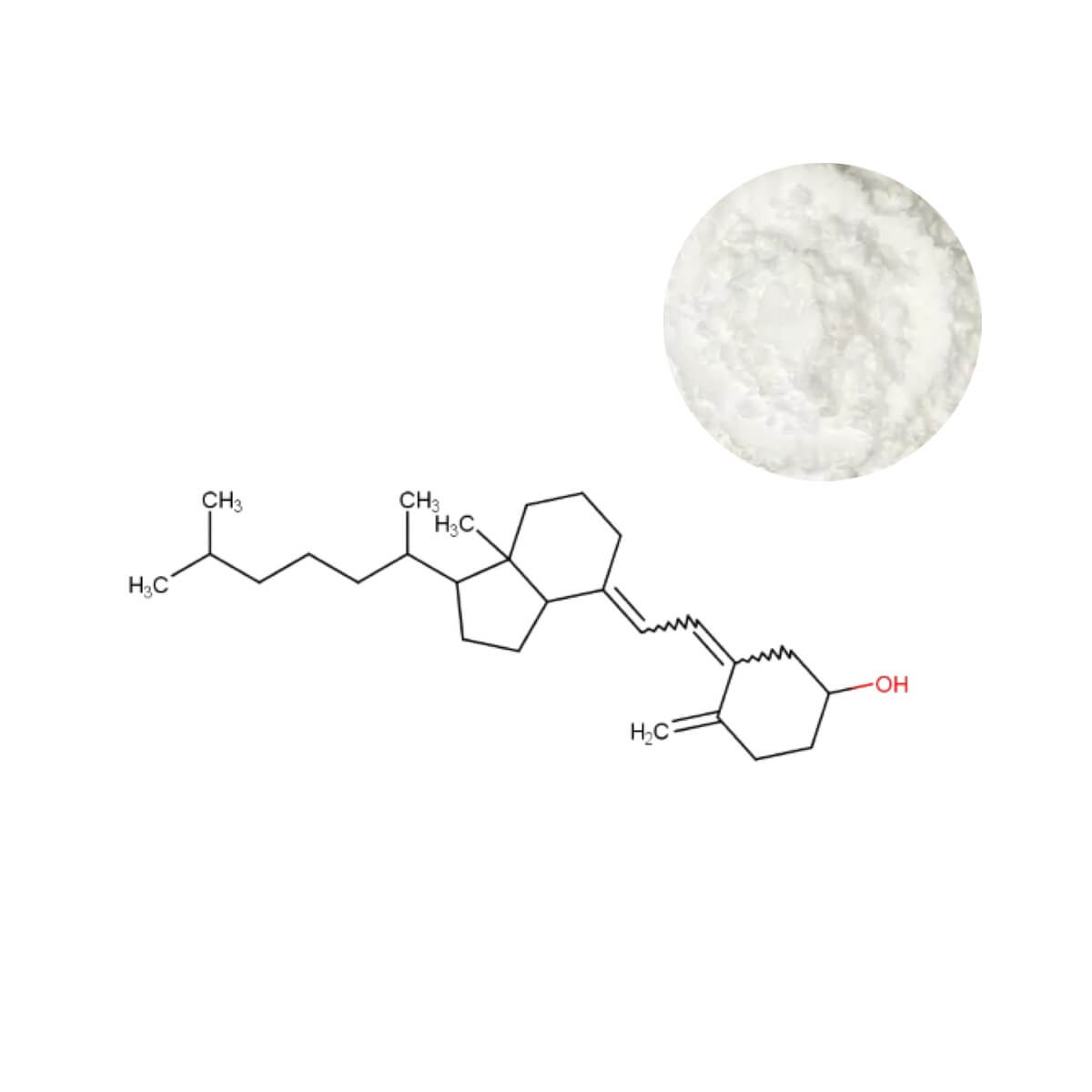

Vitamin D3 Cholecalciferol Powder

| Product Name | Vitamin D3 Cholecalciferol Powder |

| CAS Number | 67-97-0 |

| Appearance | White to off-white crystalline powder |

| Purity / Potency | 100,000 IU/g |

| Packaging | 1 kg/bag, 5 kg/bag, 25 kg/drum |

| MOQ | 1kg |

Vitamin D3 Powder: Precision Dosing & Formulation Flexibility for Modern Supplement Development

In a market where “bone health” and “immune support” claims are ubiquitous, brands face the dual challenge of substantiating efficacy and achieving manufacturing agility. The choice of your core nutrient form can dictate your entire production workflow. For formulations requiring direct dry blending—such as in powders, tablets, or gummies—a standard Vitamin D3 oil presents significant hurdles in achieving homogenous distribution and precise, low-dose delivery. This is where a premium, high-potency Vitamin D3 powder becomes a critical enabling ingredient. Standardized to a consistent 100,000 IU/g, this form factor is engineered for accuracy, allowing for seamless integration into complex blends without the need for specialized emulsification equipment. For brands sourcing bulk Vitamin D3, the move from a liquid to a dry, free-flowing powder isn't just an ingredient swap; it's a strategic decision that enhances batch consistency, simplifies scaling, and unlocks new product formats. This guide will detail how to leverage Vitamin D3 powder's technical attributes to build superior, stable, and demonstrably effective supplements.

Beyond Potency: Decoding the Quality Markers That Assure Bioavailability

While the potency specification of 100,000 IU/g is the headline figure, expert sourcing looks deeper into the parameters that guarantee this activity translates into reliable performance in the finished product. A premium Vitamin D3 powder is not simply a crystalline compound; it is typically a carefully engineered spray-dried or dry-blended system where the active cholecalciferol is uniformly distributed on a carrier like maltodextrin. This process is critical for the powder's flowability and mixability.

Key sourcing considerations include:

- Assay Method Specificity: Potency must be verified via HPLC according to a defined pharmacopoeial monograph (e.g., USP <621>). This method specifically quantifies cholecalciferol, distinct from other vitamin D metabolites, ensuring you pay for and formulate with the correct, potent form.

- Carrier and Moisture Control: The choice of carrier and a strict Loss on Drying (LOD) specification of ≤3.0% are non-negotiable for stability. A low LOD prevents clumping during storage and ensures consistent powder density, which is vital for automated dispensing and encapsulation. A key but often overlooked process detail is that controlling in-process humidity during your own blending is frequently more critical for maintaining final potency than relying on packaging alone.

- Physical Specifications for Performance: A controlled particle size (e.g., ≥95% through 80 mesh) ensures the powder will integrate without “segregating” or separating from other ingredients in a mix. This physical consistency is what underpins the promised dose uniformity in every serving of your final product.

These specifications form the foundation of a comprehensive Certificate of Analysis (CoA). A reliable supplier's CoA doesn't just list values; it provides a fingerprint of batch-to-batch consistency, directly reducing your risk of product recall or off-spec production runs.

Formulation Mastery: Stabilizing a Sensitive Nutrient for Shelf-Life Success

Vitamin D3 is inherently sensitive to light, oxygen, and heat. The powder form, by reducing surface area exposure compared to an oil, offers an inherent stability advantage, but this must be actively supported by smart formulation and processing. An effective stability strategy is multi-layered.

For dry applications like stick packs or tablet presses, the primary threat is oxidation. The solution often lies in the matrix itself:

- Synergistic Antioxidant Systems: Blending the Vitamin D3 powder with other dry, powdered antioxidants like Vitamin E (d-alpha-tocopherol) or rosemary extract creates a protective microenvironment within your blend. This is a more effective long-term strategy than relying solely on final-product packaging.

- Strategic Combination for Enhanced Efficacy: Vitamin D3's role in calcium homeostasis is well-established. Pairing it with Vitamin K2 (as MK-7) creates a powerful duo for bone health formulations, as K2 helps direct calcium to the bones. For immune support blends, combining it with zinc can address multiple facets of immune function. These combinations are not just marketing claims but are built on complementary physiological pathways.

- Process-Aware Handling: A critical piece of practical industry knowledge is that excessive heat during your own mixing or tablet compression can degrade potency. Limiting mixing time and, where possible, keeping batch temperatures below 25°C (77°F) during processing is a best practice often overlooked in pursuit of throughput.

This proactive approach to stability transforms a potential weakness into a documented quality claim, enabling stronger “guaranteed potency through expiry” labeling that builds consumer trust.

Total Cost of Ownership: Why Consistency Trumps Unit Price in Sourcing Bulk Vitamin D3

For procurement teams, the initial price per kilogram is a clear metric, but the true cost of an ingredient is found in its Total Cost of Ownership (TCO). With a foundational nutrient like Vitamin D3 powder, inconsistencies create hidden expenses that far outweigh minor upfront savings.

| Cost Factor | Low-Cost, Variable Supply Risk | Premium, Consistent Supply Advantage |

|---|---|---|

| Production Downtime | Failed QC holds production; costly line stoppages. | Pre-validated CoA ensures seamless production starts. |

| Rework & Waste | Off-spec blending requires rework or scrapes entire batches. | Predictable powder flow and density minimize waste during dispensing. |

| Regulatory & Compliance Risk | Incomplete or non-specific CoA delays regulatory submissions. | Audit-ready documentation (GMP, FSSC 22000) speeds time-to-market. |

| Brand Reputation | Potency variation leads to consumer complaints and loss of trust. | Batch-to-batch consistency guarantees label claim delivery. |

Furthermore, a partner with a dual-sourcing strategy for raw materials (e.g., lanolin and plant-derived phytosterols) provides resilience against supply shocks. Investing in a supply chain engineered for transparency and reliability is ultimately an investment in your own brand's operational stability and reputation.

Mitigating Risk: The Expert Checklist for Auditing Your Vitamin D3 Powder Supply

Selecting a partner for bulk Vitamin D3 powder requires moving beyond datasheets. It demands a due diligence process focused on verifiable systems. Use this objective checklist to assess potential suppliers:

- Documentation Depth: Do they provide a full, batch-specific CoA that includes not just potency, but also residual solvents (complying with USP <467>), heavy metals (with limits aligned to food-grade standards like FCC), and microbiological data?

- Regulatory Alignment: Can they articulate the compliant status of their material in your target markets? For the EU, is it clear their product is distinct from the authorized novel food, calcidiol monohydrate? For the US, is the GRAS or DSHEA status unambiguous? (EFSA Panel, 2024, doi: 10.2903/j.efsa.2024.8520).

- Technical Support Capacity: Do they offer formulation support or stability data for common applications (e.g., gummies, protein powders)? This indicates an investment in application science, not just trading.

- Quality System Certifications: Are their manufacturing facilities audited and certified against internationally recognized standards like GMP for dietary supplements, ISO 9001, or FSSC 22000? This is your primary proxy for consistent in-process control.

- Supply Chain Transparency: Can they trace the raw material source and provide documentation for key attributes like non-GMO or allergen status (critical for plant-derived options claiming to be free from lanolin-related allergens)?

A supplier that meets these criteria functions as a true extension of your quality team. Their rigorous controls become your first and most effective line of defense in a competitive market where quality is the ultimate differentiator.

Next Steps for Integrating Premium Vitamin D3 Powder into Your Line

Vitamin D3 powder standardized to 100,000 IU/g represents a convergence of scientific necessity and manufacturing pragmatism. It delivers the well-researched benefits of a essential nutrient—from supporting bone integrity and healthy immune function—in a format designed for precision, stability, and formulation versatility. By focusing on the detailed quality benchmarks, stabilization strategies, and supply chain rigor outlined here, brands can confidently develop products that perform reliably for consumers and withstand regulatory scrutiny.

To evaluate how this ingredient performs in your specific application matrix, we recommend a practical first step. Request a complimentary sample alongside the comprehensive technical dossier, which includes detailed CoA templates, stability study summaries, and handling guidelines. This allows your R&D team to conduct real-world tests, assessing flow, blend uniformity, and compatibility firsthand, significantly de-risking your development timeline.

Request Your Complimentary Sample & Technical DossierFrequently Asked Questions

Share this product

Related Products

Ready to get started?

Contact our team for technical specifications, pricing, and customized solutions.