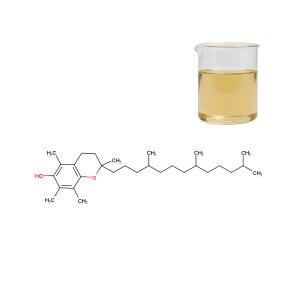

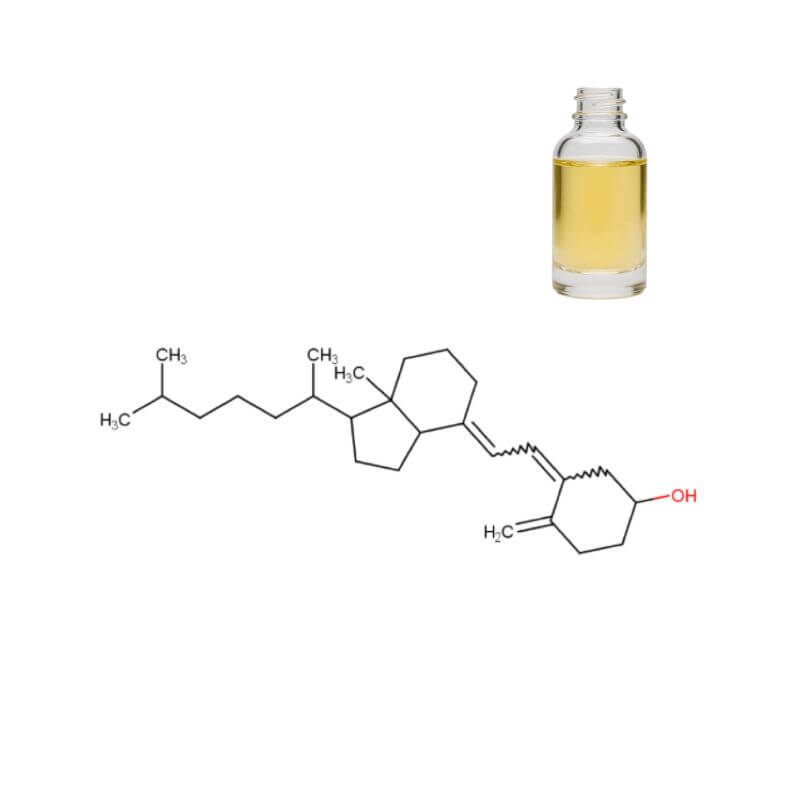

Vitamin D3 Oil

| Product Name | Vitamin D3 (Cholecalciferol) Oil |

| CAS Number | 67-97-0 |

| Appearance | Clear, pale yellow to yellow oily liquid |

| Purity / Potency | ≥1,000,000 IU/g |

| Packaging | 1 kg/bottle, 5 kg/bottle, 25 kg/drum |

| MOQ | 1 kg |

Vitamin D3 Oil: A Strategic Ingredient for Differentiated and Reliable Supplement Formulations

For brand owners and product developers, the vitamin D category presents a paradox: high consumer demand coupled with significant technical risk. The core challenge has evolved from simply sourcing the nutrient to guaranteeing its labeled potency from production through to the consumer's last dose. Today, market differentiation hinges on demonstrable stability and bioavailability—attributes determined long before the ingredient reaches your blending facility. While a premium Vitamin D3 Oil standardized to 1,000,000 IU/g is the essential starting point, its true value is unlocked through a rigorous understanding of the stability science, precise quality benchmarks, and supply chain integrity that prevent degradation. This guide provides the decision-making framework leading brands use to transform this essential nutrient from a simple cost item into a cornerstone of product integrity and market trust.

Decoding Quality: Stability Indicators That Predict Shelf-Life Performance

For procurement and quality assurance teams, a thorough evaluation of a Vitamin D3 Oil supplier requires looking beyond the basic potency assay. The predictive stability metrics on a comprehensive Certificate of Analysis (CoA) serve as your early-warning system for the ingredient's long-term behavior in your formulation. Specifications for Acid Value (≤2.0 mg KOH/g), Peroxide Value (≤10.0 mEq/kg), and stringent heavy metals limits (e.g., Lead ≤1.0 mg/kg) do more than assure compliance; they reveal a manufacturer's commitment to preventative quality control. In practice, a consistently low peroxide value confirms the oil was handled under inert nitrogen from the start—a non-negotiable practice that directly translates to a longer oxidative induction period in your final softgel or liquid. Consequently, a rigorous supplier audit prioritises transparency on these ancillary tests, as they are often stronger predictors of batch-to-batch consistency and shelf-life performance than the headline potency figure alone.

- Acid Value (≤ 2.0 mg KOH/g): Measuring free fatty acids in the carrier oil, a low and stable value indicates fresh, refined oil and minimal hydrolytic degradation. An increasing acid value in your raw material can accelerate the degradation of cholecalciferol itself.

- Peroxide Value (≤ 10.0 mEq/kg): As the most direct measure of primary oxidation, a low PV is critical. It signals protection from oxidative stress at the source, preserving the ingredient's foundational integrity for your manufacturing process.

- Heavy Metals & Residual Solvents: Adherence to strict limits for lead (≤1.0 mg/kg), arsenic (≤1.5 mg/kg), and Class 2 residual solvents (USP <467>) is a prerequisite for global market access, reflecting a supply chain governed by pharmaceutical-grade controls.

The commercial insight is clear: investing in an oil with rigorously controlled ancillary specifications directly reduces your brand's liability and failure costs, minimising the risk of accelerated stability test failures that can derail launch timelines.

The Formulation Imperative: Engineering Delivery Systems for Guaranteed Efficacy

Successfully formulating with Vitamin D3 requires a proactive defense against its known degradation pathways. Science confirms its vulnerability to metal ions and acidic conditions, with stabilization significantly enhanced by chelating agents like EDTA (DOI: 10.3390/pharmaceutics13050617). For the formulation scientist, this knowledge translates into several critical, non-negotiable design choices that determine the product's commercial viability.

- Carrier Oil Compatibility: Select an excipient oil (e.g., MCT, sunflower) with excellent intrinsic oxidative stability. Maintaining an inert nitrogen headspace—from your bulk drum to the final consumer bottle—remains the most effective barrier against peroxide formation.

- Protective Matrix Engineering: For softgels, the capsule matrix itself must be a robust barrier to oxygen and moisture. In liquid drops, including synergistic antioxidants like vitamin E and a dedicated metal-chelating agent is essential for achieving a commercially viable shelf life.

- Process Control: Minimise exposure to heat, light, and high-shear mixing during production. A frequently underestimated factor is controlling ambient humidity during powder mixing for tablets, as moisture can initiate localized degradation even in solid dosage forms.

From a development perspective, this underscores a key principle: the simplest, most robust delivery system often offers the lowest risk and highest return on investment. A well-stabilized Vitamin D3 Oil in a pure carrier, encapsulated in a quality softgel, involves fewer variables than complex aqueous blends, leading to faster development cycles and more predictable stability outcomes.

Strategic Sourcing: A Total Cost of Ownership Analysis

For procurement professionals, the true cost of Vitamin D3 Oil extends far beyond price per kilogram. A strategic Total Cost of Ownership (TCO) analysis accounts for the direct and hidden costs of ingredient failure, supply disruption, and compliance risk. The following framework illustrates how a technically proficient supplier mitigates broader business expenses:

| Cost Factor | Description | Impact of a Premium Supplier |

|---|---|---|

| Quality Failure Cost | Product recalls, rejections, out-of-spec stability results. | Drastically Reduced via rigorous CoA and full batch traceability. |

| Operational Cost | Manufacturing downtime, rework, additional testing. | Minimised through reliable solubility and simplified handling. |

| Risk Mitigation Cost | Insurance, safety stock, cost of switching suppliers. | Optimised by supply chain transparency and audit readiness. |

Therefore, a supplier's GMP certification and documentation such as FSSC 22000 represent more than checkboxes; they constitute an auditable risk mitigation system that integrates into your brand's quality defense. For brands targeting regulated markets like the EU or North America, this level of documentary support is essential for due diligence and helps prevent costly market entry delays. The strategic procurement question thus shifts from "who offers the lowest price?" to "who offers the lowest total cost of ownership and risk?"

Innovating with Confidence: Capitalising on Advanced Health Positioning

Vitamin D's established role in immune function opens sophisticated positioning avenues beyond foundational health. This allows marketing and R&D teams to leverage premium, stable Vitamin D3 Oil as a key differentiator in high-value segments. Clinically, the importance of delivery form is underscored by a 2023 randomized study where a novel oral dispersion technology yielded a significantly higher and more sustained serum response compared to standard formats (DOI: 10.3389/fnut.2023.1221685).

This research provides a critical market insight: in a crowded category, a compelling "delivery and efficacy" story can command a premium. Brands can architect distinct product narratives by targeting specific applications:

- Premium Liquid Wellness: Develop high-potency, oil-based droppers for personalised immune support routines, emphasising superior bioavailability over standard formats.

- Next-Generation Combination Products: Create synergistic blends, such as Vitamin D3 with high-concentration Omega-3s, where the oil matrix also serves as a protective medium for other sensitive actives.

- Clean-Label & Vegan Positioning: Utilise plant-derived (lichen-based) Vitamin D3 Oil in organic MCT oil to meet clean-label and vegan demands without compromising on the proven efficacy of cholecalciferol.

For product managers, this means shifting the narrative from a generic "contains Vitamin D" to a specific "guaranteed potency in a bioavailable form for targeted health outcomes," enabling a clear justification for a premium market position.

Integrating Stability by Design into Your Product Roadmap

The decision to source a high-stability Vitamin D3 Oil is a strategic investment in your product's market credibility and longevity. The technical considerations—from decoding a CoA to engineering the delivery system—form a critical path that directly impacts your brand's liability, cost structure, and consumer trust.

To apply these insights, we recommend a practical, evidence-based first step. Request a complimentary sample of GMP-certified Vitamin D3 Oil (1,000,000 IU/g) alongside the complete Technical Dossier. This dossier provides your R&D and quality teams with the objective data—detailed stability studies, full specifications, and compliance documentation—needed to validate performance claims and de-risk your development timeline. It is the essential tool for bridging the gap between ingredient specification and finished product success.

Frequently Asked Questions

Share this product

Related Products

Ready to get started?

Contact our team for technical specifications, pricing, and customized solutions.