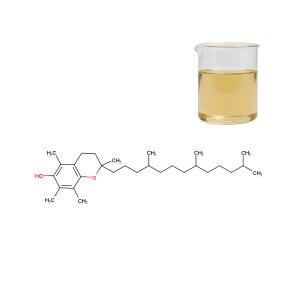

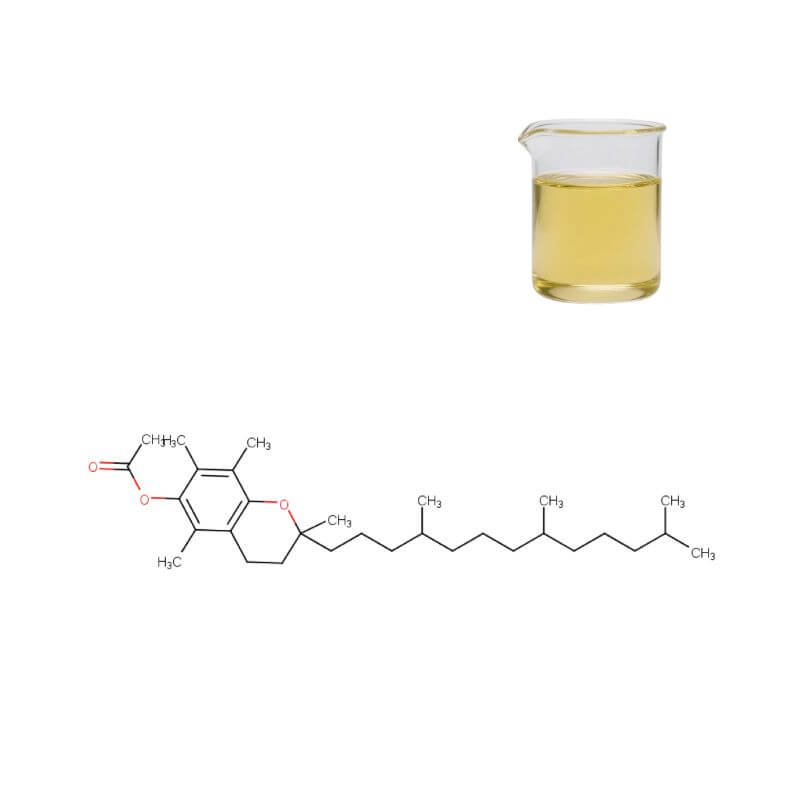

Vitamin E Acetate Oil

| Product Name | Vitamin E Acetate Oil (dl-α-Tocopheryl Acetate) |

| CAS Number | 7695-91-2 |

| Appearance | Clear, pale yellow to yellow viscous oil |

| Purity | ≥98% (by HPLC) |

| Packaging | 20 kg/drum, customizable |

| MOQ | 1 kg |

Vitamin E Acetate Oil: The Strategic Choice for Stable, High-Performance Nutraceuticals

In the competitive antioxidant market, true differentiation hinges on two pillars: scientific credibility and guaranteed product stability. The selection of your Vitamin E source is therefore a foundational decision—one that directly impacts shelf-life assurance, supply chain resilience, and ultimately, brand integrity. dl-alpha-Tocopheryl Acetate Oil represents the industry-preferred synthetic form, engineered not only for bioactivity but for exceptional stability in lipid-based systems. When sourced from GMP-aligned partners, this premium oil is standardized to ≥98% purity (by HPLC, USP <621>), a specification that serves as the primary indicator of batch-to-batch consistency. This guide delivers the strategic insights necessary to leverage this ingredient as a reliable cornerstone for your next flagship formulation.

The Science of Stability: How the Acetate Form Protects Your Investment

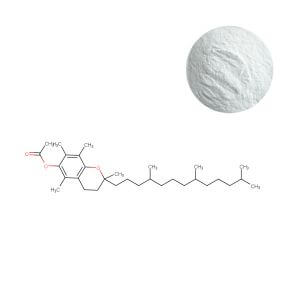

Understanding the inherent stability of dl-alpha-tocopheryl acetate is key to mitigating a major hidden cost in supplement manufacturing: potency loss before expiration. Vitamin E's core biological role as a lipid-soluble antioxidant that supports cellular health is well-established. Yet, the unesterified tocopherol is inherently susceptible to oxidation during storage and processing.

The acetate ester provides an elegant solution. It functions as a stable “pro-vitamin,” hydrolyzed in the body to release active tocopherol, while the ester bond itself offers a robust shield against oxidation in the manufacturing and shelf-life environment. For your product, this translates directly into a lower risk of failing potency assays at the end of its shelf life, thereby protecting against costly rework, recalls, or erosion of consumer trust. Consequently, while powder forms serve specific delivery needs, the oil-based acetate is the strategic default for any lipid-phase formula—from softgels to emulsified liquids—where long-term stability is non-negotiable for commercial success.

Quality as Risk Mitigation: Interpreting the CoA for Strategic Sourcing

For a mature ingredient like Vitamin E Acetate, a Certificate of Analysis (CoA) is more than a quality certificate; it is a critical risk management document. A premium supplier’s CoA provides the transparency needed to de-risk your regulatory compliance and ensure consistent batch-to-batch performance.

- Assay (HPLC, USP <621>): The ≥98% purity specification is a baseline. The true strategic insight, however, lies in the chromatographic profile that confirms the identity as pure dl-alpha-tocopheryl acetate. This verifies you are formulating with the standardized, predictable material your dosage calculations depend on, eliminating unwanted efficacy variability.

- Elemental Impurities: Specifications for key toxicants like Lead (Pb ≤1 mg/kg) and Cadmium (Cd ≤0.5 mg/kg), aligned with standards such as USP <2232>, are your first line of defense. Procuring material that proactively meets these stringent compendial limits shifts the compliance burden upstream, simplifying your own finished product testing and regulatory submissions.

- Residual Solvents (USP <467>): Full compliance is a clear indicator of advanced manufacturing and purification controls, ensuring no process-derived contaminants enter your supply chain.

For procurement teams, this makes a thorough review of full, batch-specific CoAs a non-negotiable step in supplier vetting. The oil form's inherent resistance to microbial growth—an advantage of its low water activity—further simplifies QC protocols and reduces potential biological load concerns in production.

Formulation Intelligence: Maximizing ROI in Lipid-Based Delivery Systems

The lipophilic nature of Vitamin E Acetate Oil is its primary formulation asset. Maximizing return on investment hinges on selecting the most efficient and stable delivery system aligned with your product's market positioning. The following framework outlines the strategic application logic:

| Target Delivery System | Integration Strategy & Rationale | Commercial Implication & Expert Insight |

|---|---|---|

| Softgels & Lipid-Based Capsules | Direct blending with carrier oils (e.g., MCT, sunflower oil). | Highest efficiency and potency integrity. Perfect miscibility guarantees homogeneous fill content and dose accuracy. For high-volume lines, this method minimizes processing steps and capital expenditure. |

| Emulsified Liquids & Ready-to-Drink Beverages | Incorporation into the oil phase prior to high-shear emulsification. | Enables clear, stable beverage formats. The oil form protects the vitamin from the aqueous phase. Validating emulsion stability through stress testing is crucial to prevent unsightly separation or potency drop in the final product. |

| Premium Topical Serums | Blending into lipid phases or specific emollient esters. | Delivers dual functionality (active + emollient). This supports a “clean-label” moisturizing claim in cosmeceuticals. Solubility in specific esters (e.g., C12-15 alkyl benzoate) should be confirmed for crystal-clear formulations. |

Strategic Synergy for Market Differentiation: To move beyond basic fortification, consider creating a comprehensive antioxidant network by blending with Natural Mixed Tocopherols Oil. This combination pairs the standardized, stable potency of the acetate with the broad-spectrum, naturally derived tocopherol complex, forming a strong foundation for a “complete antioxidant protection” narrative in premium product lines.

A Critical Process Note: While highly stable, the ester can be hydrolyzed under extreme conditions (prolonged high heat with strong acid/alkali). For brands exploring novel delivery systems, this underscores the importance of pilot-scale compatibility testing—a prudent step to prevent costly scale-up failures.

Sourcing for Resilience: A Total Cost of Ownership Perspective

Procuring Vitamin E Acetate Oil is a strategic exercise in evaluating Total Cost of Ownership (TCO). The choice between synthetic (dl-) and natural (d-) forms involves a clear trade-off: the synthetic form offers superior batch-to-batch consistency, unmatched oxidative stability, and insulation from agricultural commodity price volatility. This predictability is invaluable for large-scale, mainstream product lines where cost control and supply security are paramount.

A strategic sourcing approach evaluates suppliers on a risk-adjusted basis:

- Documentation & Transparency: Insist on access to full, batch-traceable CoAs and supporting stability data. This is essential for brands operating in highly regulated markets or with stringent internal quality assurance protocols.

- Regulatory Facilitation: Prioritize partners capable of supporting your market entry with appropriate documentation (e.g., GRAS determinations, EU compliance statements). A supplier that understands these needs functions as an extension of your regulatory team.

- Supply Chain Robustness: Seek evidence of resilient supply chains, such as multi-site production or strategic stockholding. For critical SKUs, continuity of supply often outweighs a marginal per-unit cost advantage from a less secure source.

From a TCO perspective, the oil form's density and efficient packaging (typically 20 kg/drums) reduce shipping and handling costs per unit of active compared to low-density powders. More significantly, its intrinsic stability minimizes the risk of catastrophic quality failures post-production. Aligning with a supplier whose operational excellence matches the ingredient's inherent stability is the final step in securing a reliable foundation for your brand.

Next Steps: Validating the Strategic Fit for Your Product Line

Integrating a stable, high-performance ingredient like Vitamin E Acetate Oil can define the reliability and efficacy of your lipid-based supplements. The strategic pathway involves moving from specification review to practical validation within your own development environment.

To proceed with confidence, a hands-on evaluation is recommended. Request a complimentary sample alongside the complete Technical Dossier. This dossier provides the granular detail—including full specifications, handling guidelines, and exemplary Certificates of Analysis—that enables your R&D and QA teams to conduct thorough due diligence. Testing the material's compatibility with your specific carriers and processes is the most effective way to de-risk your development timeline and ensure a successful product launch.

Frequently Asked Questions

Share this product

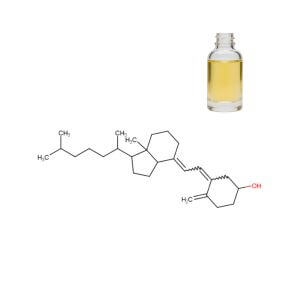

Related Products

Ready to get started?

Contact our team for technical specifications, pricing, and customized solutions.